MDF and laminate are two common panels used in construction and furniture. They have their own characteristics in raw materials, manufacturing processes, performance and application fields.

Raw materials and manufacturing processes

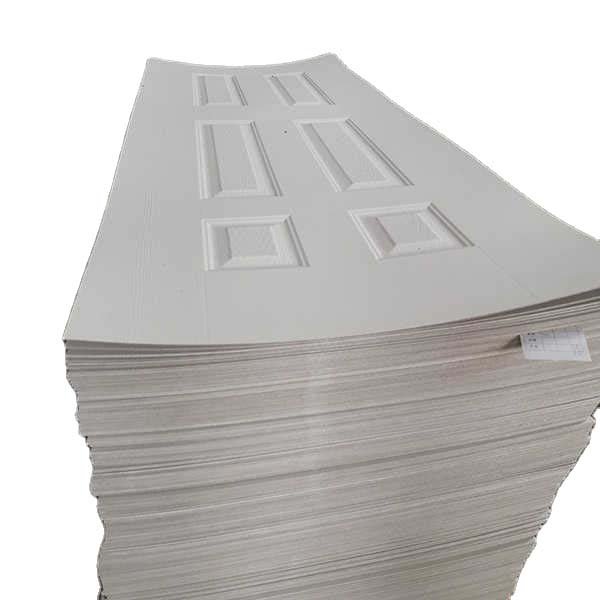

Density board: Made of fiber fibers or other plant fibers as raw materials, it is hot-pressed and formed after crushing, fiber separation, drying, applying resin or other suitable adhesives. Depending on the density, density boards can be divided into high-density boards, medium-density boards and low-density boards.

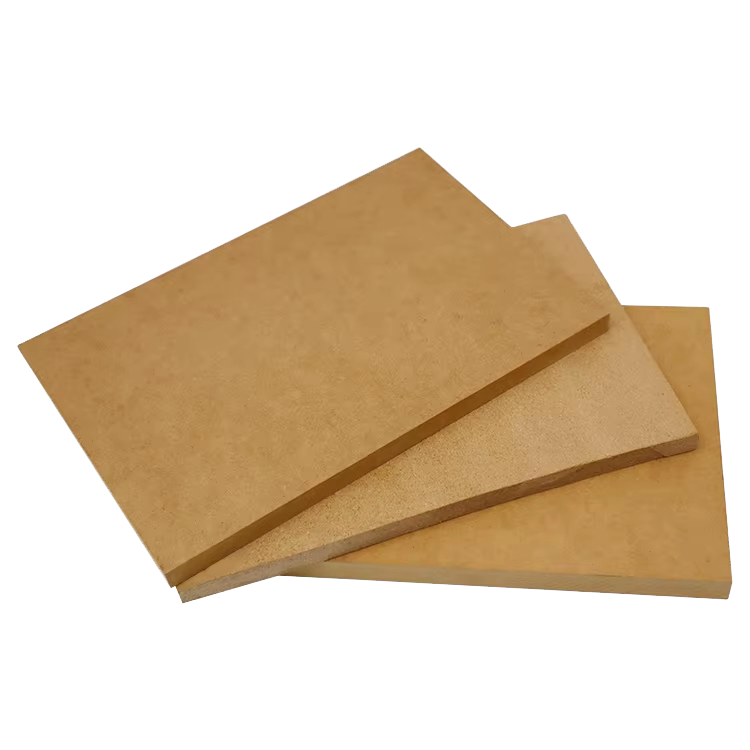

Laminate: A board made of multiple layers of wood flakes arranged perpendicularly to each other in the direction of the wood grain of adjacent layers and glued together with adhesive. Usually there is an odd number of layers, the outermost and innermost layers are veneer, and the middle layer is glulam.

Performance characteristics

Density board: The surface is flat and smooth, easy to apply various paints and veneer materials, has good processing performance, and is suitable for various mechanical processing. However, the moisture-proof performance is poor, it is easy to absorb water and swell, and the amount of formaldehyde released may be high.

Laminate: stable structure, strong bending resistance, high strength and good dimensional stability. However, the surface finish is low and may require further treatment to improve surface quality.

Application areas

Density board: widely used in furniture manufacturing, interior decoration, wall decoration and other fields. Due to its flat surface, it is suitable for use in areas that require painting or veneer.

Laminate: Commonly used in load-bearing parts such as building structures, floors, walls, and roofs. Its high strength and stability make it suitable for applications that need to bear larger loads.

When selecting boards, comprehensive considerations should be made based on specific use needs, environmental conditions and budget. MDF is suitable for non-load-bearing areas that require high surface quality, while laminate is more suitable for load-bearing areas that require high strength and stability.